| “This site contains affiliate links for which OEMDTC may be compensated” |

NTB99-032

1995-99 MAXIMA FRONT BRAKE GROAN NOISE DURING STOPPING

APPLIED VEHICLE(S):

1995-99 Maxima (A32)

SERVICE INFORMATION

Use this bulletin to service a 1995-1999 Maxima if the vehicle demonstrates a loud, low frequency groan noise coming from the front brakes during stopping. The groan addressed by this bulletin can occur at normal operating temperatures and is not a creep groan (occurring upon slight release of brakes permitting the vehicle to creep from a stopped position).

The type of noise can be duplicated during a test drive by applying the brakes several times in normal traffic conditions and using light to moderate pedal pressure. If this groan noise is duplicated before coming to a complete stop (i.e., it is not a creep groan described above), use this bulletin to correct the situation.

The cause of this incident may be frequent brake application over long periods which exposes the front rotors to high temperatures. These high temperatures may cause glazing of the rotor surface and brake pads. If this glazing has occurred, improved brake pads are available to reduce this low frequency groan noise.

SERVICE PROCEDURE

- Verify that the noise can be duplicated during a test drive by applying the brakes several times in normal traffic conditions, using light to moderate pedal pressure. Be sure that any noise is generated by the front brakes.

- If this incident occurs before the vehicle comes to a complete stop (i.e., it is not a creep groan from a stopped position), continue with Step 2.

- If the condition can not be duplicated, this bulletin does not apply.

- Resurface the front rotors. This is one of the most important steps to prevent and eliminate brake noise.

- Use an on-car brake lathe as described in Nissan

Technical Bulletin NTB92-062, “Ammco On-Car Brake Lathe Operating Guidelines”.

Technical Bulletin NTB92-062, “Ammco On-Car Brake Lathe Operating Guidelines”. - Apply slow cuts with sharp cutting tools. This produces a smooth rotor surface finish. Dull bits produce a poor cut. This leaves a rough finish that can cause noise.

- Use an on-car brake lathe as described in Nissan

CAUTION: When using an on the car brake lathe, be sure to prevent metal shavings from contacting or collecting on the ABS wheel speed sensor. Remove any shavings that stick to the ABS wheel speed sensor’s magnet.

- Hand finish the newly turned rotor surface with a non-directional swirl pattern using #150 – 180 grit aluminum oxide sandpaper. This improves the rotor surface finish and helps to further reduce noise.

- Make certain that there is no grease or metal particles left on the rotor. Use brake cleaner only for removing grease smudges from the rotor surface

- Properly install the new pads (Pad Kit P/N 41060-4L090) and shims (if required) following the instructions in the BR section of the applicable service manual.

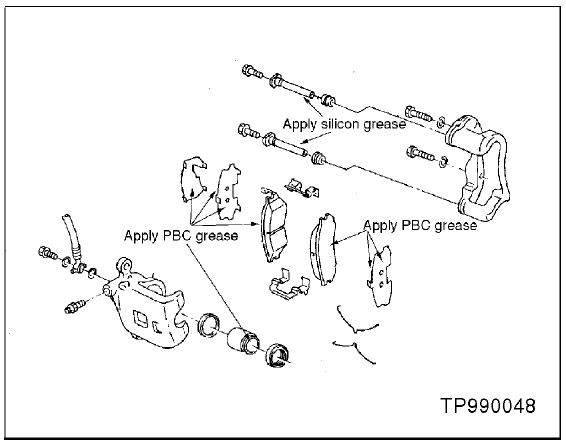

- Apply PBC grease (P/N 99990-00939) to the facing edge of the piston and to all facing surfaces between piston and pad. This will help dampen noise-causing vibrations (see Figure 1).

CAUTION: DO NOT get grease on the pad friction surface. If you do, wipe off immediately with a clean shop rag, then sand the pad friction surface with light-grit sand paper.

- Lubricate slide pins with silicon grease (P/N 999MP-AB002) and confirm smooth movement of the calipers (see Figure 1).

Figure 1.

- Torque lug nuts to 98-118 nm (10-12 kgm, 72-87 ft lbs) using a torque wrench.

CAUTION: DO NOT use an impact wrench to tighten lug nuts.

- Perform proper post-installation checks.

- Confirm that brake pads fit snugly in the calipers. Replace worn components as necessary.

- Test drive after the installation. Proper burnishing will influence brake performance including noise. Burnish brakes as follows:

- Drive the vehicle on a straight smooth road at about 30 mph (50 kph).

- Use medium brake pedal/foot effort to bring the vehicle to a complete stop from about 30 mph (50 kph). Adjust pedal/foot pressure such that the vehicle stopping time is 3-5 seconds.

- Cool the brake system by driving at about 30 mph (50 kph) for approximately one minute without stopping.

- Repeat steps 1 to 3 between 3 to 5 times to complete the burnishing process.

- Follow-up to ensure customer satisfaction, safety and proper brake performance.

- Confirm the procedures described in steps 2-5 above have been strictly followed.

PARTS INFORMATION

| DESCRIPTION | PART #/PFP | QUANTITY |

|---|---|---|

| Pad Kit | 41060-4L090 | 1 |

Loading...

Loading...